When you talk about ferrous materials (or iron) and non-ferrous, refers to metallic materials exclusively, according to the presence or absence of iron as one of its main components. For instance: pure iron, stainless steel, brass, nickel.

With the exception of pure iron (in its various grades), most of the ferrous metal It is the product of alloys or mixtures of iron and other materials, such as carbon. Non-ferrous metals can be either elemental (made up of a single atomic element) or other alloys devoid of iron.

Ferrous material properties

Ferrous materials, the fourth most common type of metal in the earth’s crust, are distinguished from non-ferrous materials in their combination of strength, malleability, great conduction of heat and electricity, as well as in the possibility of reusing them from its foundry and new forging, but above all for its high response to magnetic forces (ferromagnetism).

Thanks to the latter, ferrous material can be separated from non-ferrous in municipal waste using magnetic separation procedures.

It is due to all this that they are highly demanded at an industrial level throughout the world, constituting among the 1 and 2% of all household garbage (especially cans of food), due to its relatively low price and its great ability to alloy with other metals to gain new attributes and improve its properties.

Types of ferrous materials

All ferrous metals fit into one of these three types, according to the elements that compose them:

- Pure iron and soft iron. With very low amounts of carbon or, although rare, it is the variation that has the most iron.

- Steels. They are alloys of iron and other materials (mainly carbon and silicon), in which iron never exceeds 2% of the content.

- Foundries. They are alloys of iron and carbon with the presence of carbon or other materials in a measure greater than 2%.

Examples of ferrous materials

- Pure iron. This material, one of the most abundant on the planet, is a silver-gray metal of magnetic capacity, great hardness and density. It is considered pure when it is integrated in 99.5% of atoms of the same element and, however, it is not very useful, given its fragility (it is brittle), its high melting point (1500 ° C) and rapid oxidation to normal conditions.

- Sweet iron. Also called wrought ironIt has a very low carbon content (it does not reach 1%) and it is one of the purest commercial varieties of iron that exist. It is useful for alloys and forging, after heating it to very high temperatures and hammering it red hot, as it cools and hardens very quickly.

- Carbon Steel. Known as construction steel, it is one of the main iron derivatives produced in the steel industry and one of the most widely used in the world. It is produced from the mixture with carbon in variable proportions: 0.25% in mild steel, 0.35% in semi-sweet, 0.45% in semi-hard and 0.55% in hard.

- Silicon Steel. It is also known as electrical steel, magnetic steel, or transformer steel. It is the product of an iron alloy with a variable degree of silicon (from 0 to 6.5%), as well as manganese and aluminum (0.5%). Its main virtue is having a very high electrical resistance.

- Stainless steel. This iron alloy is very popular, given its high resistance to corrosion and the action of oxygen (oxidation), a product of its manufacture from chromium (10 to 12% at least) and other metals such as molybdenum and nickel.

- Galvanized steel. This is the name given to steel covered with a layer of zinc, which, being a much less oxidizable metal, protects it from air and considerably slows down its corrosion. This is extremely useful for making pipe parts and plumbing tools.

- Damascus steel. The origin of this specific type of alloy is supposed to be in the Middle East (the Syrian city of Damascus) between the 11th and 18th centuries, when swords made of this material were widely quoted in Europe, due to their great hardness and “almost eternal” edge. . It is still debated what exactly was the technique used to obtain it at the time, although today it has been replicated for a wide range of knives and iron cutting utensils.

- Steel “wootz”. This steel is traditionally obtained by mixing iron residues (ores or pig iron) with charcoal of vegetable origin and glass, in furnaces at high temperatures. This alloy has many carbides that make it particularly hard and non-deformable.

- Iron foundries. This is the name given to the high carbon content alloys (typically between 2.14 and 6.67%) that are subjected to iron to obtain substances of higher density and brittleness (white cast iron) or more stable and machinable (gray cast iron). ).

- Permalloy. It is a magnetic alloy of iron and nickel in various proportions, characterized by high magnetic permeability. Its electrical resistivity changes by 5% of the amplitude of the magnetic field, which makes it ideal for making sensors, magnetic heads and other implements in the industry.

Examples of non-ferrous materials

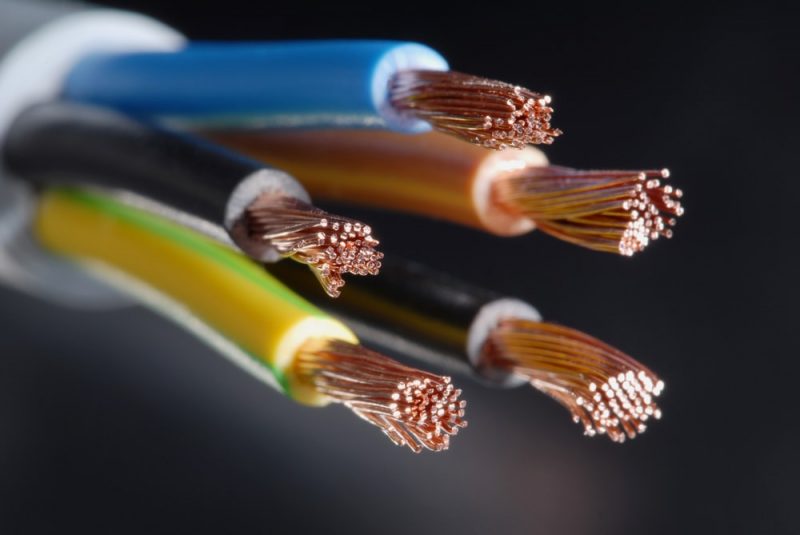

- Copper. With the chemical symbol Cu, it is one of the elements of the periodic table. It is a ductile metal and a good transmitter of electricity and heat, which is why it is used abundantly in telecommunications and not so much in tasks that require toughness.

- Aluminum. Another great electrical and thermal conductor, aluminum is one of the most popular metals today, due to its low density, lightness and low oxidation, as well as extremely low toxicity, making it ideal for making food containers.

- Tin. Commonly used to protect steel from oxidation, it is a relatively dense and brightly colored metal that, when bent, emits a crunch that is called “tin scream”. It is very soft and flexible at room temperature, but when heated it becomes brittle and brittle.

- Zinc. It is highly resistant to rust and corrosion, which is why it is often used in galvanizing processes. This element is lightweight and inexpensive, which is why it is in high industrial demand.

- Brass. It is an alloy of copper and zinc (between 5 and 40%), which improves the tensile strength of both metals without taking away their lightness and low density. It is widely used in the manufacture of hardware, plumbing parts and tools in general.

- Bronze. With a copper-based alloy and an addition of 10% tin, this alloy is more resistant than brass and highly ductile, which has played a very important role in the history of mankind, to the point of giving its name to an age of civilization. It is used in statues, accessory pieces and keys, among many other uses.

- Magnesium. Very abundant in the earth’s crust and dissolved in the waters of the sea, this metallic element constitutes certain ions essential for life on the planet, despite the fact that it is not usually found in a free state in nature, but as part of larger compounds. Reacts with water and is highly flammable.

- Titanium. Lighter than steel, but also more resistant to corrosion and of such hardness, it is an abundant metal in nature (never in its pure state) but expensive for man, so it is not widely used. It is used in the manufacture of medical prostheses very frequently.

- Gold. It is a precious metal, perhaps the best known and most coveted given its commercial and economic appreciation. Its color is bright yellow and it is a ductile, malleable and heavy element that reacts with cyanide, mercury, chlorine and bleach.